Five Tips for Buying a Foodservice Pump

Five Tips for Buying a Foodservice Pump

Since the early days of America’s culinary history, pumps have been used to dispense toppings and flavors into drinks or onto dessert items. Think of the old-fashioned Soda Fountains housed in pharmacies, candy shops and department stores back in the 1930s, ‘40s and ‘50s. A smiling proprietor dressed in all white stands behind the counter ready to take your order, whether it is a soda, sundae or malt. If you were to stand on your tippy-toes and peek over the counter, you’d see a long serving bar with several polished stainless steel pumps that dispense flavorful goodness with every press.

Although an old-fashioned Soda Fountain is rare this day and age, the pumps and dispensers originally used in these establishments can be found in all segments of the foodservice industry today. The ketchup dispenser at your favorite quick serve’s condiment station, or behind the scenes at the wing joint – somehow there’s always a perfect amount of wing sauce. The pumps baristas use to add your favorite seasonal flavoring to that latte or blended coffee drink, and the best part of a ball game – watching golden, melty cheese fill the dish in your nacho platter with a simple press. Whether they’re located back-of-house at the finishing station or near the condiment and beverage island, foodservice pumps and dispensers are right where you need them, serving the right amount of condiments, syrups, dressings, sauces, gravies and so much more.

For a foodservice operator, pumps and dispensers are invaluable. They provide access to products in their original containers, maintaining the kitchen’s smooth operational flow. Some pumps are more mobile, allowing a food container to be moved to the most convenient location. Flavor and brand graphics or color-coded knobs and levers simplify product identification for a fast-paced work environment. A dispenser’s portion-control capability helps employees minimize the chance of over portioning expensive ingredients while controlling costs for operators. Pumps deter portion pack scavengers from pilfering packets and prevent empty packets from being strewn across the condiment station. Restaurant chains love pumps as they ensure a consistent taste quality regardless of restaurant location or who is preparing the menu item; the customer experience is consistent across the entire restaurant system.

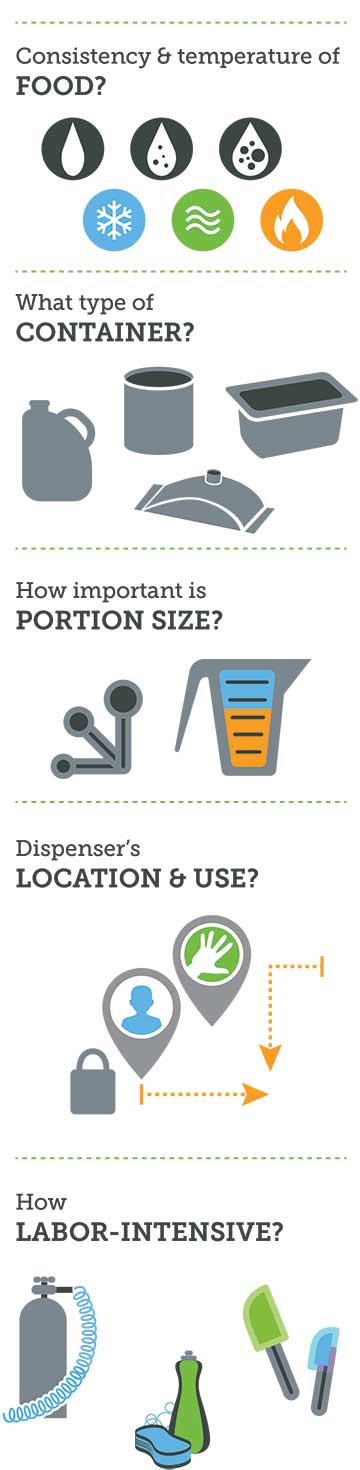

With endless design and material options, as well as different dispensing applications, it’s important to ask the right questions while you shop around for the most appropriate dispenser. Here’s a list of questions and considerations when investing in the best pump for your foodservice operation.

1. What type of product will you be dispensing?

Viscosity, or how fluid a product is, determines if a product is pumpable or if a different serving method is necessary. The food’s consistency influences which style pump is most applicable, and what size and shape discharge tube will best handle it.

Certain pumps can handle particulates – think dressings with seeds, tartar sauce, and salsa; many house-made sauces have variable-sized particulates. Other pumps are shaped to prevent thin products like drink concentrates and syrups from dripping. Be sure the pump can handle the food you need to dispense – a clogged or dripping pump won’t do your operation any good.

Knowing if the product will be heated, chilled or kept ambient – or room temperature – is crucial when selecting the type of material; some plastics cannot be used in heated applications, so stainless steel may be necessary. Certain pump varieties can keep a product like fudge warm and fluid – even in the discharge tube – with a spout warmer. Whether it’s a taste preference or you’re dispensing a dairy-based product, the ability to keep an entire pump chilled will affect your selection as well. Potentially hazardous foods require a chilled discharge tube. Certain certifications, such as NSF, signify if pumps are safe for your particular product. A lack of certification could be a liability.

2. What type of container are you dispensing out of?

Food manufacturers offer a wide breadth of container types: 1 liter bottles, a 1 gallon or 64 oz jugs, a 3, 4 or 5 liter bucket, a #10 can, various sized pouches or bags with fitments, and many others. Fountain jars, food pans or stainless steel jars hold artisan sauces for dispensing from cold tables, warmers and more. If you’re looking to be more cost effective and Eco-friendly, research if your desired foods are available in pouches before deciding on which pump to purchase.

Product volume also influences container types – high-demand foods require larger containers. Ketchup in three-gallon pouches will utilize a different pump than beverage flavoring in a bottle or fountain jar.

Certain pump vessels are branding-ready. Many food manufacturers are procuring their own pumping systems for their product and branding them accordingly giving the operator an attractive and complete system for handling their product.

Each food holding method integrates with a pump differently – resting on top of a pan, piercing a fitment, threading onto a bag, etc. Be sure your pump is the right size and has the correct pickup mechanism.

3. How important is portion size to you?

While some pumps come with one preset portion, such as 1 oz disposable pumps, others offer precision and adjustability. Pumps with accurate, reliable portion control save money, as well as keep flavors consistent at each location in a chain. Over-portioning costs hard-earned money, so if exact portions are a must-have, invest in a pump with more capabilities.

4. Where will the dispenser be located and how will it be used?

A dispenser at an amusement park or stadium concession stand will need to be more tamper-resistant than a back-of-house pump, and should be able to handle a higher volume. For these situations, pouched dispensers are ideal – the airtight seal prevents contamination, and pouch changeouts take minimal time. If pouches aren’t an option, look for pump and container assemblies with threaded or locking lids.

If a pump is located at a self-serve condiment station, is it easily accessible for children and customers with wheelchairs? Many pumps have in-counter models to keep them at an appropriate height. Are there other ergonomic considerations to keep in mind? Look for pumps certified as ADA compliant, meaning they can be operated with less than 5 lbs of pressure, and don’t involve unnatural wrist movements.

Some pumps can be assembled in stations where an assortment of flavors is needed, such as the classic ice cream shop fountain rail or a wing restaurant’s back-of-house finishing station.

5. How labor-intensive is it?

While CO2 dispensers are common in high-volume locations, they are expensive, cumbersome to change, and often spit product while engaged. Mechanical remote dispensers are available at a fraction of the cost, and are much easier to load and unload.

Plastic, disposable pumps, while initially inexpensive, add up in cost but require no cleaning – just throw them away with an empty container. For a slightly larger investment, you can purchase higher quality pumps that last decades, but require cleaning. Some of these more durable pumps have clean-in-place capabilities for quicker cleaning.

While product pouches are relatively new to the industry, they promote higher product evacuation while reducing cleaning labor. Containers like gallon jugs and #10 cans currently provide more options for food product, but unless they are scraped out near the end of use, a lot of product is wasted.

Food pumps and dispensers have a long history in the foodservice industry. From dispensing soda flavors in a 1950’s corner drug store to providing the same precise shot of pumpkin spice in a global coffee chain shop in Chicago, USA as in Melbourne, Australia. They stand the test of time because they improve operational efficiency, control costs and maintain product quality. Picking the right pump and asking the right questions can make all the difference.